We produce high transparency rigid pet film.

our high quality pet film can be used for blister packing, clear rigid pet film for Blister Packaging.

Pet blister film,blister polyester film

Blister pack is a term for several types of pre-formed plastic packaging used for small consumer goods, foods, and for pharmaceuticals.

The primary component of a blister pack is a cavity or pocket made from a formable web, usually a thermoformed plastic. This usually has a backing of paperboardor a lidding seal of aluminum foil or pet film.

Our film also can be used but not limit to below applications.

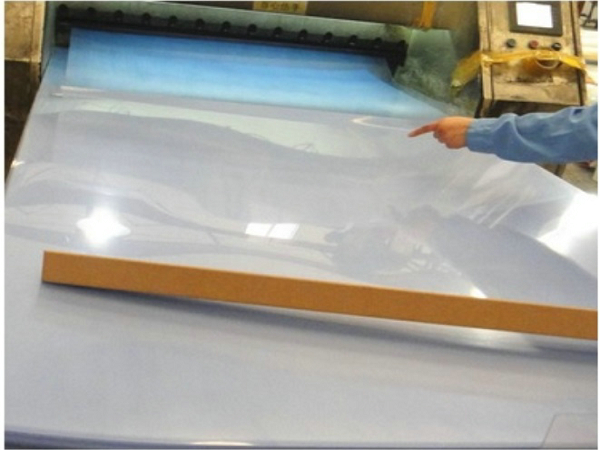

Rigid pet film for screen printing

Rigid pet film for Thermoforming

Rigid pet film for UV Offset-Printing

Rigid pet film for blister packing