- worldclass facility,pet films,stamping foils for you

- sales@chinabopetfilm.com

printing Pet film

Clear pet film for printing,pet film for inkjet printing,pet film for offset printing,pet film for heat transfer printing.

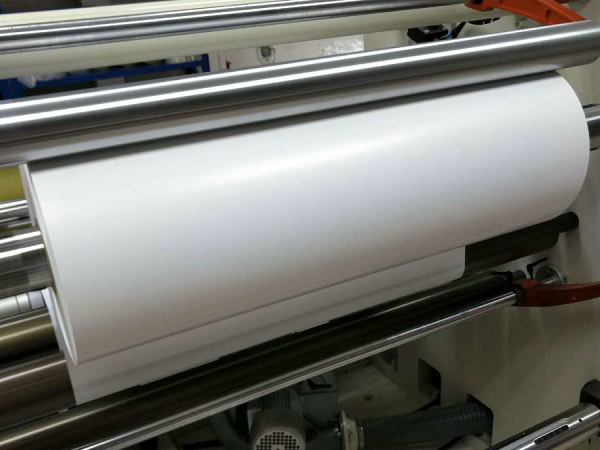

We have clear corona treated pet film,chemically treated pet film,matte pet film,white pet film,rigid pet film for printing.

BOPET film without treatment, the surface wet tension could be 38 dynes or more, but in order to further improve the printing ink or metallzing .it is better to increase the PET film surface wet tension to have a better adhesion for the ink and metal. PET film surface treatment methods are: corona treatment, chemical treatment, coating, etc.

Corona treatment method is based on the principle: by the metal electrode and the corona treatment roller (usually high temperature, ozone resistant, high insulation silicone rubber roller) between the high frequency, high voltage power supply, so that the discharge, so that Air ionizes and forms a lot of ozone. At the same time, high-energy sparks strike the surface of the film. Under their joint action, the plastic film surface is activated and the surface energy is increased. The corona treatment can make the surface tension of BOPET film reach 52 ~ 56 dynes or even higher.

Chemically Coated pet film is another effective way to improve the surface properties of BOPET films. The so-called coating method is coated on the film surface layer of a polymer , such as acrylates, copolyester and other polymer solution coating.

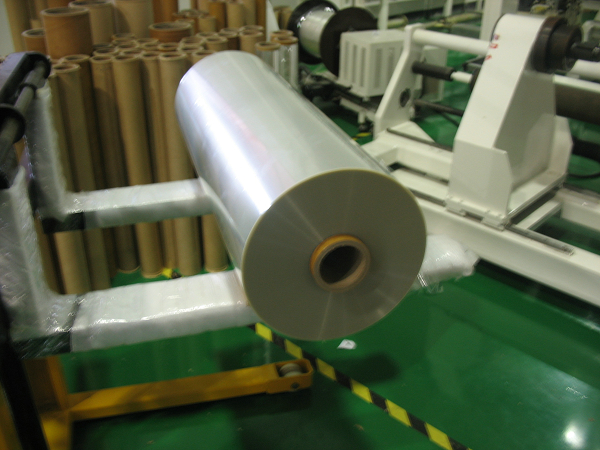

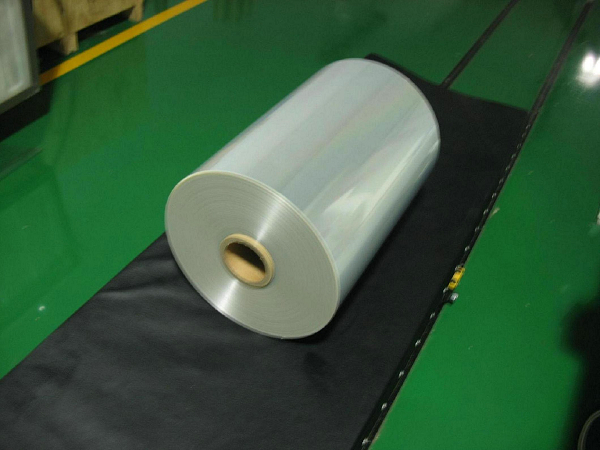

Our pet film thickness range from 10-250mic

12mic, 23 mic ,50 mic pet film for printing and lamination.

75 mic ,100 mic corona treated pet film for printing and lamination.

125 micron corona treated pet film for printing and lamination.

150 micron corona treated pet film for printing and lamination.

188 micron corona treated pet film for printing and lamination.

Maximum width:2250mm

Standard packing: suspension pallet

Paper core: 3inch or 6 inch

Please feel free to contact us for TDS and quotations.