- worldclass facility,pet films,stamping foils for you

- sales@chinabopetfilm.com

Thermoforming film material and process

Thermoforming film material and production process

Vacuum Thermoforming normally use ABS plastic sheet, PVC Plastic film, PET film, PC film, pp films, & hips, acrylic.

Here we would like to introduce our PET film and PVC film for thermoforming.

PVC film is the most commonly used vacuum thermofoming materials, it is soft, strong toughness, Good thermal plasticity, can be made transparent and a variety of colors, commonly used transparent PVC film for electronics packaging, cosmetics, toys, gift boxes and other products.

PET film/Apet film :APET (Amorphous-polyethylene terephthalate) is a thermal plastic and part of the polyester product family. It provides unsurpassed gloss and transparency for the ultimate in product visibility. APET is utilized in a broad range of applications, including vacuum forming, food and non-food packaging, folding and set-up boxes, stationery, as well as printing and graphics.

PET film is more environmentally friendly to replace PVC

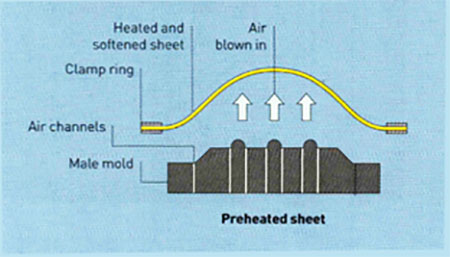

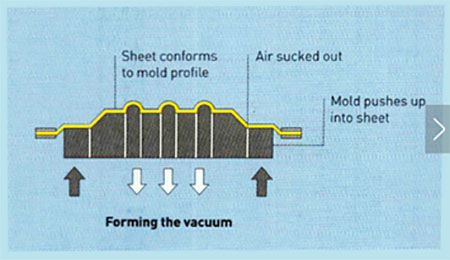

Vacuum thermoforming procedure: preheating-forming-CNC finishing

Step 1: Heat & soften PET film (yellow color in the illustration)

Step 2: The internal air through the suction hole of male mould is taken out, soften the embryonic form of plastic flakes under the pressure of the air adsorption in the male mould surface molding, cooling curing, for trimming process.

Please contact us for more details of thermoforming films.

mail to Sales@chinabopetfilm.com