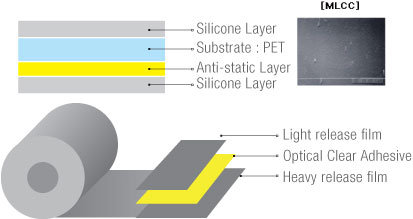

Our pet film for MLCC with high cleanliness, low surface roughness, excellent flatness, dimensional thermal stability, great appearance, reusable.

after coated silicone material on our pet film,the release film has moderate surface roughness and thickness uniformity and its excellent application in various purposes and process conditions allows it to be used in temporary supporter and adhesion level protection. It is currently used as a base for ceramic dielectric forming process such as Multi-Layer Ceramic Capacitor’s (MLCC) laminating ceramic condenser.

Application:used for release film of MLCC.